Manufacturing

Supporting our vision of driving innovative solutions for future mobility.

Quality Driven

Safety Focused

People Powered

Leading with Precision

Driving Innovation

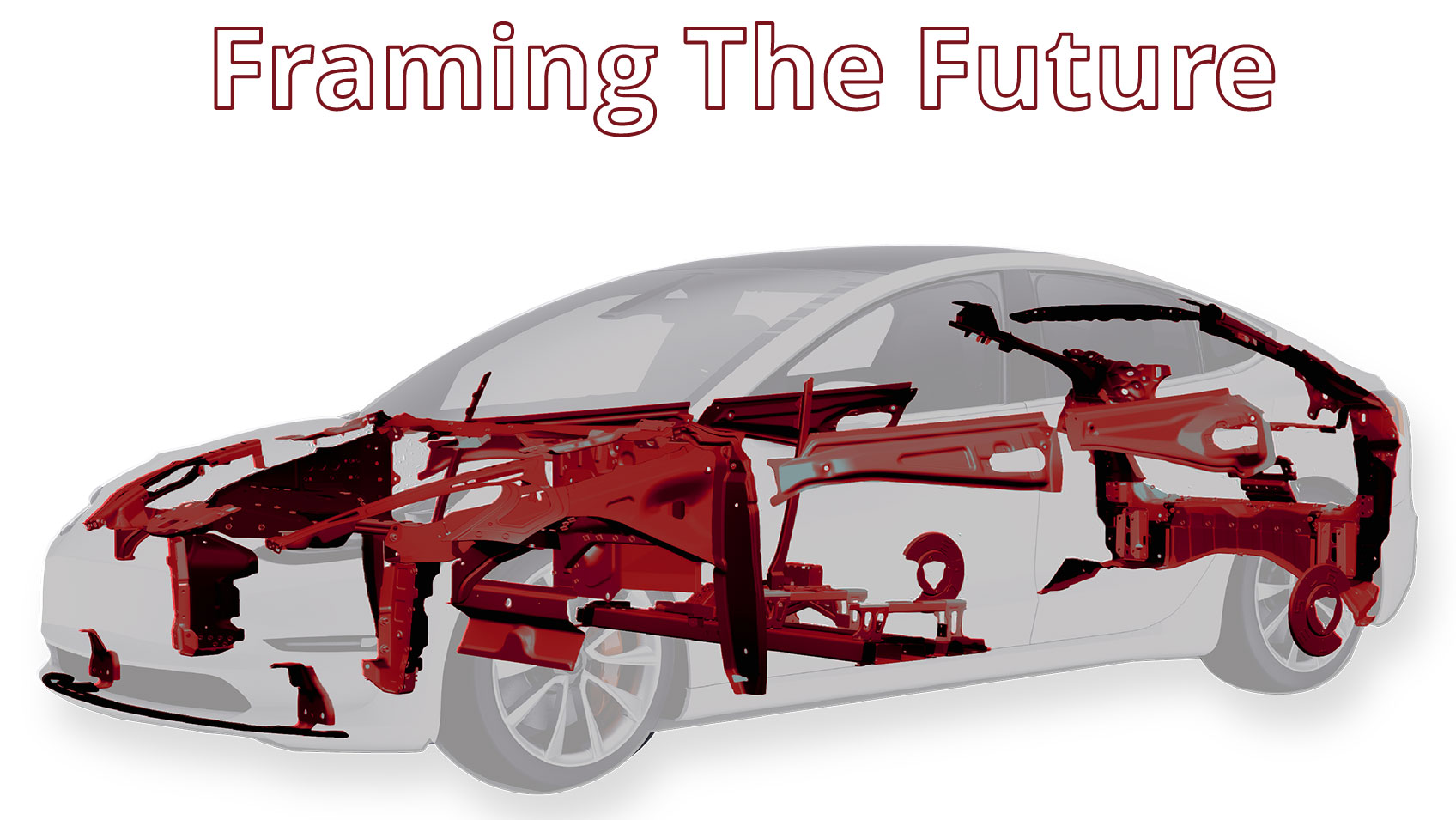

At Challenge, our diverse manufacturing capabilities consistently meet the dynamic demands of the automotive industry. From mastering electric vehicle technology to adapting to the latest materials and innovative processes, we ensure we stay ahead in a rapidly evolving market. Through our expertise in metal stamping, complex assembly, and welding, we support our customers. Committed to cost-effective solutions and powered by leading-edge automation, we seamlessly expand alongside valued long-term customers, upholding the highest standards of quality.

Innovating Automotive Excellence

With Metal Forming

As a premier Tier 1 automotive provider, we specialize in welded assemblies and engineered metal-formed products. Embracing cutting-edge technologies, including state-of-the-art robotics, has transformed our operations, ensuring a harmonious blend of human expertise and advanced automation. Today, our commitment to precision, speed, accuracy, and quality shines through in the construction of complex assemblies, utilizing series aluminum extrusions, hot-formed and press-hardened steel, and high-pressure die-cast aluminum.

Delivering quality

Metal Stamping

Challenge features a complete suite of in-house metal forming capabilities and has leading experience supplying other processed forming options to OEMs through 137 stamping presses including tandem press lines with capabilities ranging from 100 – 2,750 tons, and 32 material grades. Leveraging our expansive size and nationwide presence, we excel in delivering complex products at scale, while also providing supplementary forming options through our established industry partnerships. Our expertise extends to the precision formation of intricate vehicle underbody and upper body structures, as well as roof assemblies, achieved through advanced techniques such as high-speed progressive stamping and high-tonnage transfer processes.

Welding

With Precision

With an ever-evolving landscape of vehicle components and materials, precision welding techniques are paramount to meeting and exceeding buyer expectations. At Challenge Manufacturing, we rise to these challenges with confidence, leveraging industry-proven welding methods to ensure the production of high-quality, efficient products that align with customer demands. We specialize in many types of welding including, resistance, projection, MIG, laser, joining solutions, and drawn arc stud welding. Our strategic application of these fabrication techniques throughout the manufacturing process underscores our commitment to delivering dependable results consistently, on time, and within budget.